Yuri Bilinsky, New Pathway – Ukrainian News.

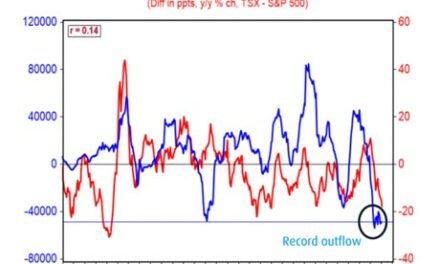

The congestion at the Canadian West Coast ports is currently not as bad as at the California ports. According to Bloomberg, on October 22, there were 112 ships in the Los Angeles/Long Beach port as compared to 21 ships in the Port of Vancouver. This is driving cargo shipments from the twin LA / Long Beach port to the Port of Vancouver, according to the anecdotal evidence from two industry experts which NP-UN interviewed last week.

However, the situation at the Port of Vancouver is already bad enough. “It’s absolutely chaotic here. Our customers are losing their minds,” Tom Johnson, head of media relations for the Port Transportation Association (PTA), told JOC.com in early October.

This is where the now notorious strain in the Canadian supply chain starts. Transportation companies, which deliver containers in and out of the ports, cannot return empty containers to the ports and are running out of space in their yards to store the containers. Many trucking carriers have run out of space in their yards and have containers on their chassis.

Because of the chaos at the ports, the transportation companies are accumulating inefficiencies and penalties due to the fewer than normal number of trips. At the same time, frustrated retailers and retail customers cannot receive their goods for months. The strain has reached exporters which are having problems shipping their goods out of Canada.

Julia Kuzeljevich, Director of Policy and Communications at the Canadian International Freight Forwarders Association (CIFFA), told NP-UN that the foundations of the current strain were laid at the beginning of the pandemic when a lot of shipping capacity was taken out of the system – fewer cargo ships were sailing and the number of passenger flights, which carry a lot of cargo, was drastically reduced.

At the same time, the demand for goods in Canada spiked because people were spending much less on services and travel while the government’s assistance programs have supported their purchasing power.

This imbalance between the demand and capacity of the supply chain has caused long-term ripple effects which are getting worse on the verge of this year’s winter holiday season.

Tanya Petryshen, Executive Vice President at Distributors’ Choice, a logistics company out of Mississauga, ON, explained to NP-UN that she has advised her customers to have their holiday product at her warehouse by the beginning of October, or risk not receiving Christmas orders due to the enormous logistic backlog.

Distributors’ Choice is now looking at a repetition of the 2020 Christmas season when it worked six days a week, many of the staff double shifts and overtime: “Honestly, your body starts to physically give, you mentally give, we weren’t made to work like that”, said Petryshen.

E-commerce volumes were so great last year that, although the company had only six clients, fewer than normally due to the pandemic, it had to triple its staff. This situation was hard to manage because it is possible to fit only so many people within six feet before one runs out of room even in a large warehouse.

Distributors’ Choice, as a favour to its clients, is now accepting items that Petryshen never thought the company was capable of handling, such as home appliances: clients need to process them amid the supply chain backlog, otherwise the entire truck orders get cancelled and go back to the manufacturer.

The trucking industry, another vital part of the supply chain, is having challenging times as well. Zoriana Workun, Director of Eastern Operations at Caravan Group of Companies based in Oakville, ON, told NP-UN that Canadian trucking companies are feeling a lot of pressure from higher costs that isn’t translating to higher freight rates.

“Operating properly and according to the law is expensive”, said Workun. She believes that the government needs to do a better job at regulating the trucking industry and hammering down on the companies that don’t follow the rules: “it would be good to level the playing field, we need the same rules applied to everyone”, she said.

The government’s slow reaction to the trucking industry’s challenges was evident when it took 18 months since the onset of COVID-19 to impose the rule that truck drivers need to have access to washrooms, noted Workun.

Workun, whose father was a truck driver, admits that nowadays a career in trucking is not considered as “cool” as it was in her father’s time. This contributes to the deficit of truck drivers that exacerbates the supply chain crunch. Workun believes that trucking needs to be more admired within our society. Acknowledging truck driving as a skilled trade would be a big step, she noted. That would also change the trucking companies’ ability to hire foreign workers. She noted further challenges of attracting more people into the truck driving career as it is a lifestyle that doesn’t necessarily boast the work-life balance that many people are seeking.

Last week, CIFFA’s Executive Director Bruce Rodgers addressed Prime Minister Justin Trudeau with a request to take leadership in solving the supply chain crunch. He provided the American example where the U.S. President Biden took action – securing agreements from ports, trucking firms, labour unions to make an emergency effort to address the crisis.

Since a new Minister of Transport (Omar Alghabra was appointed to this role on October 26 – NP-UN) will be swamped with complex files, CIFFA urged the PM to name a special representative with no other duties but to bring parties together and to craft a national response to “the supply chain disaster”.

Share on Social Media